Crystal Cylinder-yokutidwa ndi golide-Kupaka golide Ndi Kuyika Kwamkuwa

Mafotokozedwe Akatundu

Ma laser ang'onoang'ono a slab laser crystal lasers amatha kupeza mphamvu zambiri komanso mtengo wabwino wamtengo pogwiritsa ntchito njira yowotcherera, koma kwa makristalo akulu akulu (≥100mm2), njira yowotcherera yachikhalidwe iyi imakhala ndi ma voids akulu (≥ 1mm2), malo akulu ozungulira, komanso kugawa kwa solder kwa wosanjikiza sikuli kofanana. Izi makamaka chifukwa chakuti slab laser crystal imatenthedwa m'malo opanda vacuum, kutentha kwa kutentha kumayenda pang'onopang'ono, ndipo kutenthetsa ndi kuziziritsa kumakhala pang'onopang'ono, zomwe zimapangitsa kutentha kosiyana kwa kristalo wa laser slab, ndipo ndikosavuta kupangitsa kuti gawo la solder lisungunuke, gawo litatha kusungunuka, ndipo gawo la solder lisungunuke kaye. Solidification, gawo lina la zochitika zapambuyo-solidification. Choncho, panthawi yotentha ya slab laser crystal, gawo la solder lomwe limasungunuka poyamba limamaliza kuwotcherera ndi kutuluka, kuzungulira gawo losasungunuka, lomwe ndi losavuta kupanga mavuto monga voids, soldering pafupifupi ndi kugawa kosagwirizana kwa solder. M'kati mwa kuzizira, m'mphepete mwa slab laser crystal nthawi zambiri imakhazikika poyamba. Choncho, solder m'mphepete solidifies choyamba, ndiyeno akamazizira olimba mbali yapakati. Gawo lamadzimadzi limasandulika kukhala gawo lolimba ndipo limakonda kuchepa kwambiri, lomwe limakonda kukhala ndi voids ndi soldering pafupifupi.

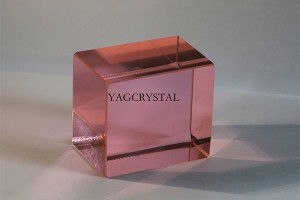

Kampani yathu imatha kupereka ntchito zokutira golide ndi copper plating. Kumata kwa golidi ndi ndodo za krustalo, zokutira zagolide za malata. Ntchito yake ndi yakuti kristaloyo imatha kuwotcherera mwamphamvu pamadzi otentha, ndipo imathanso kutaya kutentha kotero kumapangitsa kuti mtengowo ukhale wabwino.